Page 302 - IRSEM_Main Book

P. 302

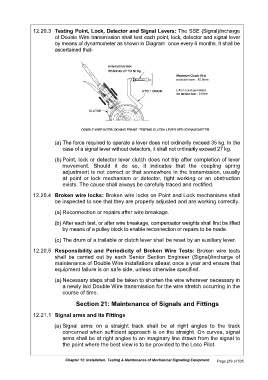

12.20.3 Testing Point, Lock, Detector and Signal Levers:Testing Point, Lock, Detector and Signal Levers: The SSE (Signal)/The SSE (Signal)/incharge

of Double Wire transmission shall test each point, lock, detector and signal lever of Double Wire transmission shall test each point, lock, detector and signal lever of Double Wire transmission shall test each point, lock, detector and signal lever

by means of dynamometer as shown in Diagram once every 6 months. It shall be by means of dynamometer as shown in Diagram once every 6 months. It shall be by means of dynamometer as shown in Diagram once every 6 months. It shall be

ascertained that-

(a) The force required to operate a lever does not ordinarily exceed 35he force required to operate a lever does not ordinarily exceed 35he force required to operate a lever does not ordinarily exceed 35 kg. In the

case of a signal lever without detectors, it shall not ordinarily exceed 27 kg.case of a signal lever without detectors, it shall not ordinarily exceed 27 kg.case of a signal lever without detectors, it shall not ordinarily exceed 27 kg.

(b) Point, lock or detector lever clutch does not trip after completion of lever Point, lock or detector lever clutch does not trip after completion of lever Point, lock or detector lever clutch does not trip after completion of lever

movement. Should it do so, it indicates that the coupling spring movement. Should it do so, it indicates that the coupling spring movement. Should it do so, it indicates that the coupling spring

adjustment is not correcadjustment is not correct or that somewhere in the transmission, usually t or that somewhere in the transmission, usually

at point or lock mechanism or detector, tight working or an obstruction at point or lock mechanism or detector, tight working or an obstruction at point or lock mechanism or detector, tight working or an obstruction

exists. The cause shall always be carefully traced and rectified.exists. The cause shall always be carefully traced and rectified.exists. The cause shall always be carefully traced and rectified.

12.20.4 Broken wire locks:Broken wire locks: Broken wire locks on Point and Lock mechanisms shall Broken wire locks on Point and Lock mechanisms shall

be inspected to see that they are properly adjusted and are working correctly.be inspected to see that they are properly adjusted and are working correctly.be inspected to see that they are properly adjusted and are working correctly.

(a) Reconnection or repairs after wire breakageReconnection or repairs after wire breakage.

(b) After each test, or after wire breakage, compensator weights shall first After each test, or after wire breakage, compensator weights shall first After each test, or after wire breakage, compensator weights shall first be lifted

by means of a pulley block to enable reconnection or repairs to be made.by means of a pulley block to enable reconnection or repairs to be made.by means of a pulley block to enable reconnection or repairs to be made.

(c) The drum of a trailable or clutch lever shall be reset by an auxiliary leverThe drum of a trailable or clutch lever shall be reset by an auxiliary leverThe drum of a trailable or clutch lever shall be reset by an auxiliary lever.

12.20.5 Responsibility and Periodicity of Broken Wire Tests:Responsibility and Periodicity of Broken Wire Tests:Responsibility and Periodicity of Broken Wire Tests: Broken wire tests

shall be carried out by each Senior Section Engineer (Signal)ried out by each Senior Section Engineer (Signal)ried out by each Senior Section Engineer (Signal)/incharge of

maintenance of Double Wire installations atleast once a year and ensure that maintenance of Double Wire installations atleast once a year and ensure that maintenance of Double Wire installations atleast once a year and ensure that

equipment failure is on safe side, unless otherwise specified. equipment failure is on safe side, unless otherwise specified. equipment failure is on safe side, unless otherwise specified.

(a) Necessary steps shall be taken to shorten the wire Necessary steps shall be taken to shorten the wire wherever necessary in wherever necessary in

a newly laid Double Wire transmission for the wire stretch occurring in the a newly laid Double Wire transmission for the wire stretch occurring in the a newly laid Double Wire transmission for the wire stretch occurring in the

course of time.course of time.

Section 21Section 21: Maintenance of Signals and FittingsMaintenance of Signals and Fittings

12.21.1 Signal arms and its FittingsSignal arms and its Fittings

(a) Signal arms on a straight track shall be at right Signal arms on a straight track shall be at right angles to the track angles to the track

concerned when sufficient approach is on the straight. On curves, signal concerned when sufficient approach is on the straight. On curves, signal concerned when sufficient approach is on the straight. On curves, signal

arms shall be at right angles to an imaginary line drawn from the signal to arms shall be at right angles to an imaginary line drawn from the signal to arms shall be at right angles to an imaginary line drawn from the signal to

the point where the best view is to be provided to the Loco Pilot.the point where the best view is to be provided to the Loco Pilot.the point where the best view is to be provided to the Loco Pilot.

Chapter 12: Installation, Testing & Maintenance 12: Installation, Testing & Maintenance of Mechanical Signalling Equipmentf Mechanical Signalling Equipment Page 256 of 535